Resurrecting My Snowblower: A Journey from Junk to Juggernaut

Introduction#

Since it’s February 14th, I’d like to wish you a Happy Valentine’s Day! Now, getting back to the main focus of this entry… let me remind you, twelve days ago, Phil saw his shadow. Yes, I know it’s all tradition and superstition, but up until Groundhog Day, we had no snow. Since then, in the northeast, we’ve had three storms! So it is safe to say that winter is in full swing! Driveways have been transformed into a form of manual labor and daunting tasks - snow removal!

Leading up to this season, I thought I was prepared for a season of easy snow removal since I received a used snowblower. In the past, my driveway, which is rather large in my opinion, had to be shoveled by hand and that task was my sole responsibility. With a 2 year old last year, my wife would watch him play in the snow or keep my son entertained in the house while I took care of the chore of clearing the driveway and walkways. This year though, I thought my job would be easy. I am now the owner of a Poulan PR621 Pro that I obtained last summer. Prior to taking it, I tested the unit and confirmed that it both started up and the auger spun. I truly believed that I’d be in good shape for winter, but boy was I was wrong! After the first snowfall of the season, when I pulled the snowblower outside and filled the tank with gas, the unit started but I quickly learned that something was wrong! Any bit of snow over one tenth of an inch or a quarter of a centimeter would cause the auger to seize. So I ended up breaking out the shovel again to finish the cleanup after the storm. At first I considered getting rid of the snowblower, but then I gave it more thought and like anything else I encounter, I don’t succumb to defeat so easily. My thought process was that a broken snowblower wasn’t much different from a malfunctioning server or network issue; it was just another system with failing components that needed attention.

Faced with future storms predicted, I shoveled out my driveway and refused to let a non-functional snowblower get the best of me. I embarked on a hands-on adventure to breathe new life into a neglected machine!

The Initial Diagnosis#

The first step was a thorough assessment, much like running a diagnostic scan on a failing system:

- Visual Inspection: The motor looked okay, but the carburetor bowl was in bad shape. It was very rusted and the gasket was dried out.

- Operational Test: Engine struggled to maintain RPM’s and you could hear it revving up and slowing down in succession. The auger spun, but any real resistance would cause it to stalled under minimal load.

Using my google-fu skills that I’d normally apply towards tech problems, I began scouring the internet to see if I could find any posts or message boards that were similar to what I was experiencing. I did find many posts and resources online in which my observations pointed towards issues with the carburetor, governor springs, and auger belt.

Troubleshooting and Repairs#

Armed with some basic ‘weekend mechanic’ tools and a systematic approach, I tackled each problem methodically.

1. Carburetor Replacement#

- Problem: A faulty carburetor can choke the engine, leading to poor performance.

- Research: Identified the compatible carburetor model for my snowblower.

- Replacement: Carefully removed the old carburetor, noting the linkage positions, and installed the new one.

- Outcome: The engine roared back to life, running smoothly without sputtering.

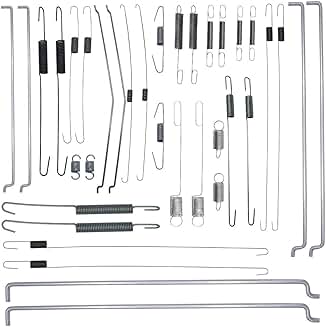

2. Governor Springs Replacement#

- Problem: Worn governor springs can cause the engine to misregulate under load.

- Identification: Located the governor springs connected to the throttle.

- Installation: Replaced the fatigued springs with new ones, ensuring proper tension.

- Outcome: The engine maintained consistent RPMs, adapting well to varying snow densities.

3. Pull Starter Repair#

- Problem: A frayed pull cord made starting the engine a hassle.

- Assessment: Found the cord had weakened near the handle.

- Repair: Trimmed the damaged section and retied the knot securely.

- Outcome: Starting the snowblower became effortless, with a reliable recoil action.

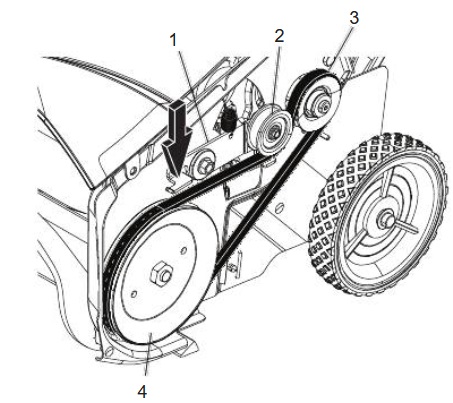

4. Auger Belt Replacement#

- Problem: A loose auger belt rendered the snowblower ineffective against heavy snow.

- Accessing the Belt: Removed the belt cover to expose the drive system.

- Replacement: Installed a new belt, ensuring proper alignment and tension.

- Outcome: The auger engaged robustly, propelling snow distances of 15-25 feet with ease.

5. Oil Maintenance#

- Problem: Maintaining proper lubrication is vital for engine longevity.

- Oil Check: Noted the oil level was low and slightly overfilled after topping off.

- Adjustment: Drained excess oil to achieve the optimal level, preventing potential leaks.

- Outcome: The engine operated smoothly, with no signs of oil leakage.

The Triumph of Hands-On Troubleshooting#

Through methodical troubleshooting and a willingness to get my hands dirty, I transformed a dormant snowblower into a winter workhorse. This journey underscored the parallels between mechanical repairs and tech problem-solving:

- Systematic Approach: Breaking down complex issues into manageable tasks.

- Research and Learning: Utilizing manuals, forums, and tutorials to inform each step.

- Persistence: Embracing trial and error as a pathway to success.

Just as in tech troubleshooting, understanding the fundamentals and approaching problems methodically can demystify even the most daunting mechanical challenges. With approximately $70 invested in parts and supplies, I not only saved money but also gained invaluable experience and the satisfaction of self-reliance.

Embrace the challenge, and you might find that fixing a snowblower isn’t so different from debugging code.